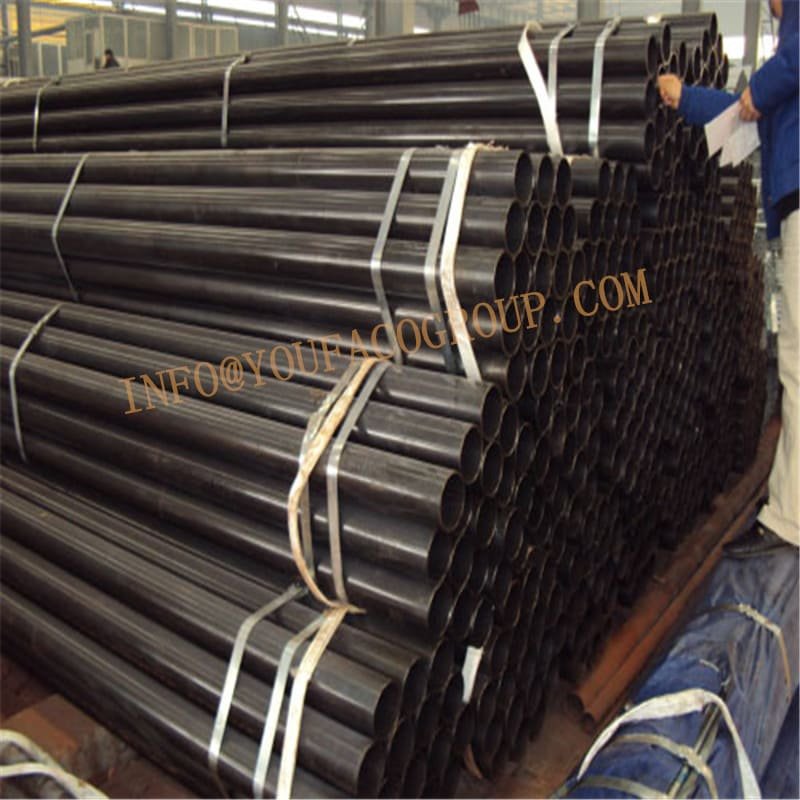

Black scaffolding pipes

Standard: EN39, BS 1139, JIS 3444, AN1576, EN10219, ASTM36, etc.

Surface: Zinc coating 30-100g/m2

Authentification: SGS/ISO9001:2000

Grade/Material:

Q195 = S195 / A53 Grade A,

Q235 = S235 / A53 Grade B ; Q235/Q345

Usage: Construction

Ends: Plain ends Or Threaded ends

Section Shape: Round/Square

Description

BLACK SCAFFOLDING PIPES

Scaffolding Pipe Specifications

YOUFACO’s Scaffolding Pipes are Conformed to Scaffold Standard of BS 1139, EN39, EN10219, JIS 3444, AS 1576, ASTM36 etc. We Produce Galvanised and Black Scaffolding Pipes In All Diameter. Include 48mm, 60mm, 42mm etc. As a professional and advanced scaffold manufacturer in China, YOUFACO offers a scaffolding pipe with different types and sizes to choose. For the types, you can choose whether hot-dip galvanized scaffolding pipe, scaffolding welded scaffold tube, steel scaffolding pipes, and more.

| Standard | EN39, BS 1139, JIS 3444, AN1576, EN10219, ASTM36, etc. |

| Surface | Zinc coating 30-100g/m2 |

| Authentification | SGS/ISO9001:2000 |

| Grade/Material | Q195 = S195 / A53 Grade A,

Q235 = S235 / A53 Grade B ; Q235/Q345 |

| Usage | Construction |

| Ends | Plain ends Or Threaded ends |

| Section Shape | Round/Square |

| MOQ | 20 TON/ONE Container |

| Port | Xingang Tianjin Port in China |

| Package | Packed in bundle,suitable for sea transport; According to the clients’requirements. |

YOUFACO scaffolding pipes are manufactured with standard Q235/Q345 carbon steel. Our scaffolding pipes are manufactured and designed for tube and coupler scaffold. They provide good appearance and sufficient durability especially under the condition of salty air or long-term weather exposure.

Types of The BS1139 GI Scaffolding Pipes

GI Scaffolding Pipes are Required in Most Construction Companies and Oil Gas Contractors. It is Hot Dip Galvanized in O.D 48.3mm. There are 2 Main Types of GI Scaffolding Pipes:

- Type 4 GI Scaffolding Pipes: Size of Type 4 GI Pipes are in O.D 48.3mm x. 4.0mm Thickness.

- Type 3 GI Scaffolding Pipes: Size of the Type 3 Pipes are in O.D 48.3mm x 3.2mm Thickness.

Thinner Wall Thickness of O.D 48.3mm GI Pipes thickness Include of 1.6mm, 1.7mm, 1.8m, 2.0mm, 2.2mm, 2.4mm, 2.5mm, 2.7mm, 2.9mm, 3.0mm etc.

In Singapore, Japanese and Korea, Sri Lanka Countries, GI Scaffolding Pipe in 2.4mm JIS 3444 Standard is Popular Used.

Emboss Marks of GI Scaffolding Pipes BS1139

Scaffolding Pipe with Marks BS 1139

According to the BS1139 Scaffolding Standard, GI Scaffolding Pipes Should Include Emboss Marks:

- Standard Code No.

- Manufacturer Track No.

- Manufacturing Month and Year

- Type of Pipes

For Example BS1139 WM 10/20 Type 4

Zinc Thickness of The GI Scaffolding Pipes

According to the BS1139 Standard, GI Scaffolding Pipes Zinc Thickness Should Be Not Less Than 40 Micro.

Ms Black Scaffold Pipes

Black Scaffold Pipes O.D 48.3mm is the Most Used Steel Scaffolding Material, As Raw Elements of Producing Modular System Scaffolding Include Ringlock Scaffolding, Cuplock Scaffolding, Kwikstage Scaffolding, Tube Lock Scaffolding, Heavy-Duty Shoring Frames, Acrow Props Etc.

The thickness of the Black Scaffold Pipes Include 4.0mm,3.2mm, and 3.0mm

Black Scaffold Pipes are Imported by Scaffolding Companies Aboard China.

Steel Grade of BS1139 Scaffolding Pipes

BS1139 Scaffolding Pipes Steel Grade Include S235, S275, S355 for Both GI and Black Types. According to the Steel Grade, S355 Scaffolding Pipes are High Yield and Tensile Strength to Ensure a Bigger Load Capacity.

S355 Steel Grade Scaffolding Pipes are used to Produces Vertical Standard and Ledgers of the Modular System Scaffold for Stable and Great Safety Load.

YOUFACO Scaffolding Pipes Test

YOUFACO Scaffold Produces All Types of BS1139 Scaffolding Pipes GI and Black. The Company has its own Test House Controlling Scaffolding Pipe

Quality from the Following Steps:

1) Steel Grade of Raw Material

Scaffolding Pipe Raw Material is Steel Plate. Only Tested Past Steel Plate Coil are Approved Accepted in Raw Material Stock. Raw Material Testing Including Chemical Composition According to BS1139, Physical Property of Tensile Strength, Yield Strength, Elongation.

2) Welding Line Testing

Scaffolding Pipe Welding Line Quality is Tested According to ISO3834 and EN1090 CE Requirement. While Flatten Testing is also Essential in Scaffolding Pipe Welding Line Testing.

3) Finished Scaffolding Pipe Testing

GI Scaffolding Pipes are Tested After Galvanizing, While Black Tube are Tested after Welding Directly.

The Testing Include Chemical Composition, Physical Property and Flatten

Clients Can get Mill Certificated, Test Report from Wellmade for Each Batch of Material

For more than 10 years, we became experts in manufacturing scaffolding pipe then shipping it to Europe, North America, Southeast Asia, and throughout the world.

Packing and Delivery

Packing Details : in hexagonal seaworthy bundles packed by steel strips, With two nylon slings for each bundles.

Delivery Details : Depending on the QTY, normally one month.