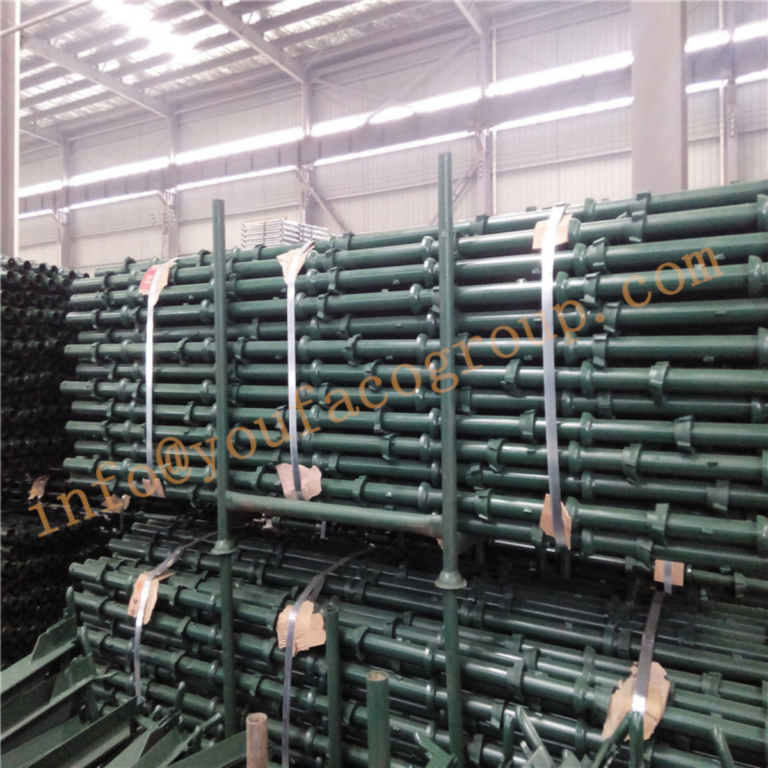

What is the Average Lifespan of Cuplock Scaffolding?

Factors Affecting Lifespan

Material Quality

The type of steel used in cuplock scaffolding is a crucial factor. High-quality, corrosion-resistant steel can significantly extend the lifespan. For example, the scaffolding made of hot-dip galvanized steel, which has a thick zinc coating, can better withstand environmental factors such as moisture and chemicals. The zinc coating acts as a sacrificial anode, corroding first and protecting the underlying steel. The expected lifespan of hot-dip galvanized cuplock scaffolding is around 10 – 15 years or more.

Usage Frequency

The using frequency is also an important consideration. For instance, scaffolding used daily for heavy-duty construction work, may have a shorter lifespan than scaffolding used intermittently for light-duty projects.

Load-bearing Cpacity

The load-bearing capacity also affects lifespan. If the scaffolding is consistently overloaded beyond its designed capacity, it can lead to structural damage such as deformation of the tubes and joints. The cuplock joints, in particular, can become loose or damaged under excessive loads, reducing the overall safety and lifespan of the scaffolding.

Environmental Conditions

The climate and environmental exposure also play a significant role. In regions with harsh winters, where the scaffolding may be exposed to freezing temperatures, ice, and snow, there is a risk of cracking due to thermal expansion and contraction. In addition, exposure to ultraviolet (UV) radiation from the sun can cause the degradation of plastic components and fading of paint finishes, which may affect the scaffolding’s appearance and its durability.

In areas with high levels of industrial pollution, such as factories or chemical plants, the scaffolding may be exposed to corrosive gases and particulate matter. These pollutants can react with the scaffolding’s surface and accelerate the corrosion process.

Maintenance and Storage

Regular maintenance is essential for prolonging the lifespan of cuplock scaffolding. This includes cleaning the scaffolding to remove dirt, debris, and corrosive substances, as well as inspecting for any signs of damage such as cracks, bent tubes, or loose joints. Applying a protective coating, such as a rust-inhibiting paint, during routine maintenance can also help.

Proper storage when the scaffolding is not in use is equally important. Storing the scaffolding in a dry, sheltered area can prevent exposure to moisture and other environmental factors. If the scaffolding is stored outdoors without proper protection, it can quickly deteriorate due to rain, wind – blown debris, and other elements.

Average Lifespan Estimates

Under normal usage conditions, with proper maintenance and storage, and in a relatively mild environment, cuplock scaffolding can last around 7-10 years. This estimate assumes that the scaffolding is used for typical construction projects with normal load-bearing requirements and is made of good – quality, galvanized steel.

However, in more extreme conditions, such as heavy use in a harsh industrial environment without adequate maintenance, the lifespan could be as short as 3 – 5 years or even less.